It is time to take the next step in warehouse automation and focus on the handling of individual items – a task that still mostly is handled manually can now efficiently be done by a robot.

The HKM robot has a reach exceeding that of a person, works effortlessly 24×7 and requires a minimum of maintenance. It is the natural complement to the increasing number of automated storage and retrieval systems as well as package sorting systems. Most logistics companies today are looking for new solutions to match their need for higher pick speed, more flexibility in workforce planning and a more effective use of their resources. With an increased robotization, handling of individual articles and packages offers an improved productivity, higher pick quality and the freedom to scale and operate your business independent of the hour of the day or day of the week. An automated item handling is the missing piece to enable a fully automated order fulfillment process.

The HKM combines superior pick speed, long reach, great payload capacity with high tool flexibility to offer you an almost endless amount of automation opportunities to innovate you warehouse processes.

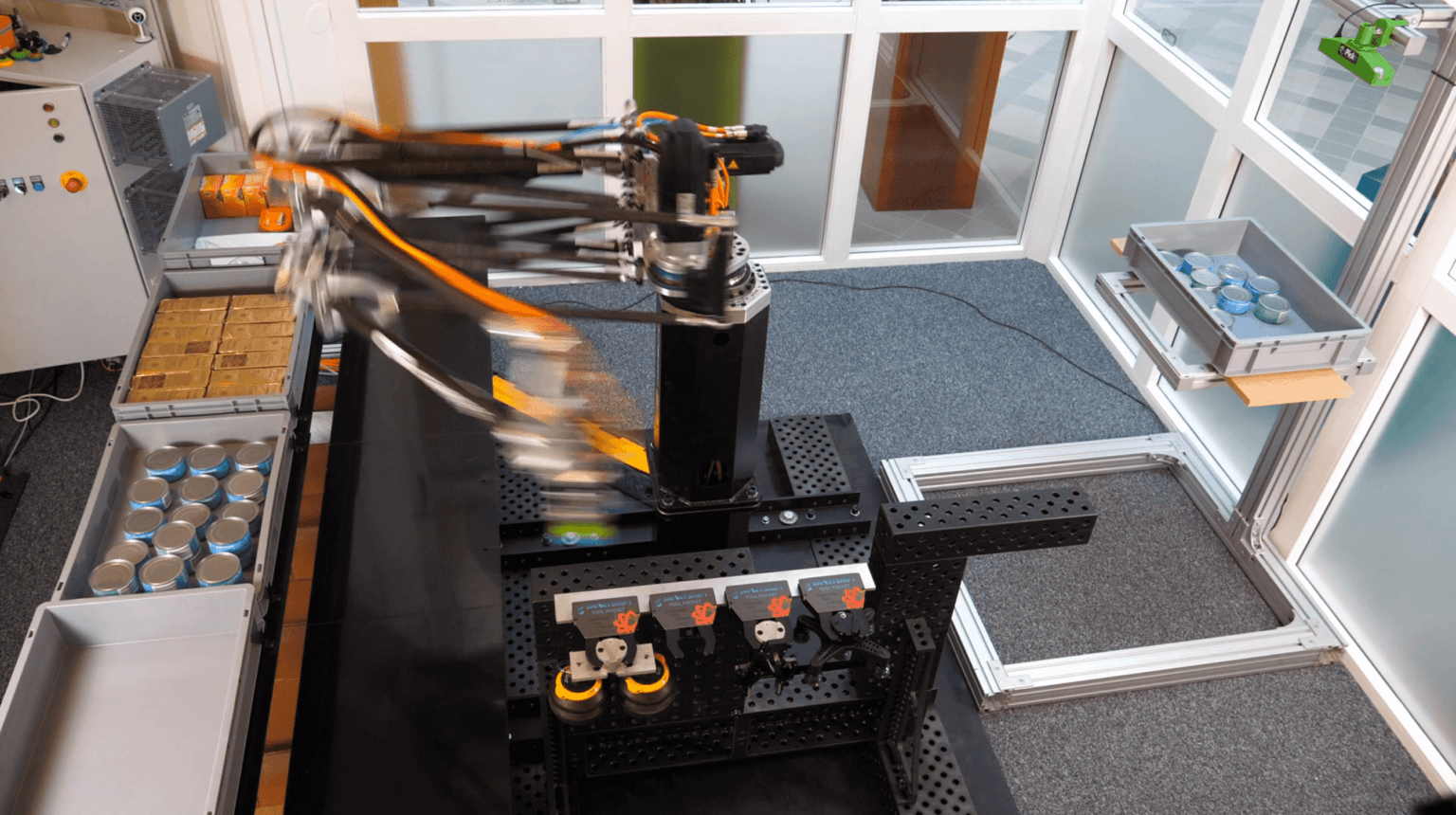

The HKM robot is a fast material handling robot with pick cycles down to 1 sec per pick, up to . 4-5 times faster than manual picking. This speed means you can get the most out of your warehouse storage systems and get your orders out more quickly than ever before.

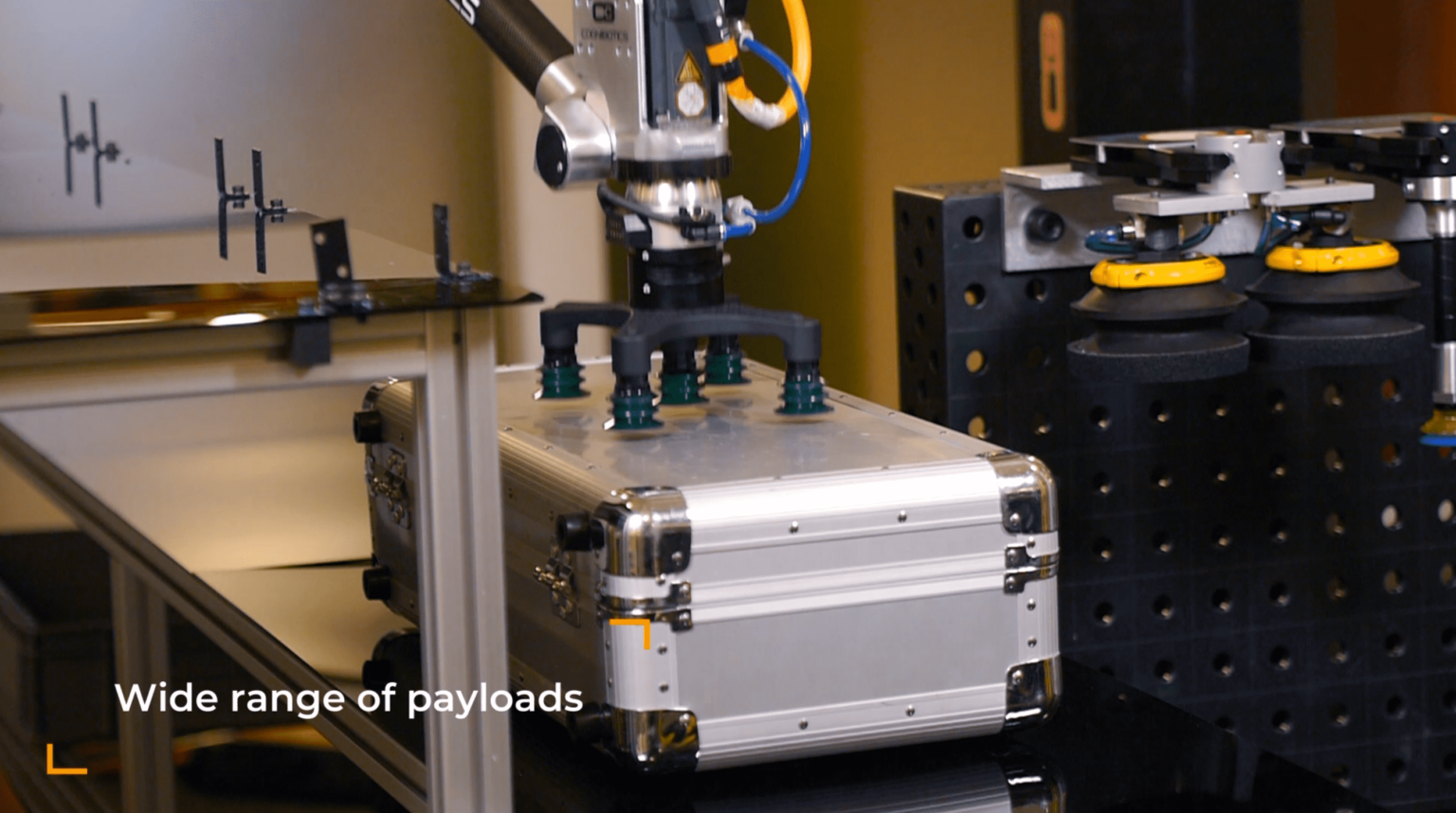

Based on the type of item the HKM robot can be equipped with different tools to pick almost any item you put in front of it, just as a person would.

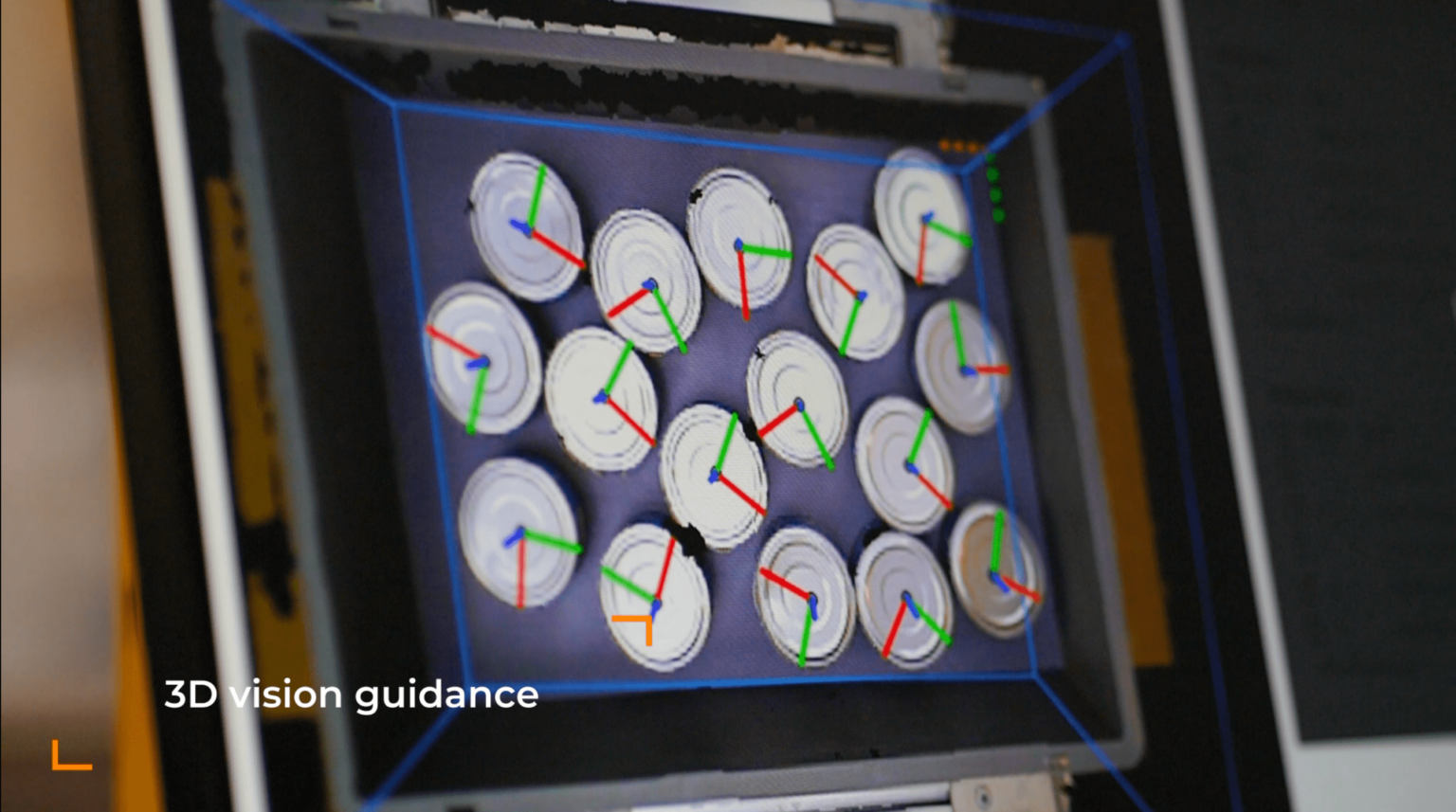

Equipped with modern camera solutions the robot can easily find the right object and decide how to pick it, regardless of order in the bins where they are stored. It is designed to handle reality where lack of order and variety of different articles is the norm. AI based algorithms enables the robot to handle several thousands of different articles even without having seen them before.

The ability to select and quickly change to the most suitable tool for the job at hand drastically increases not only what type of article the robot can handle but also the number of different tasks the robot can complete. With an integrated tool changer the robot does this in just over 1 s!

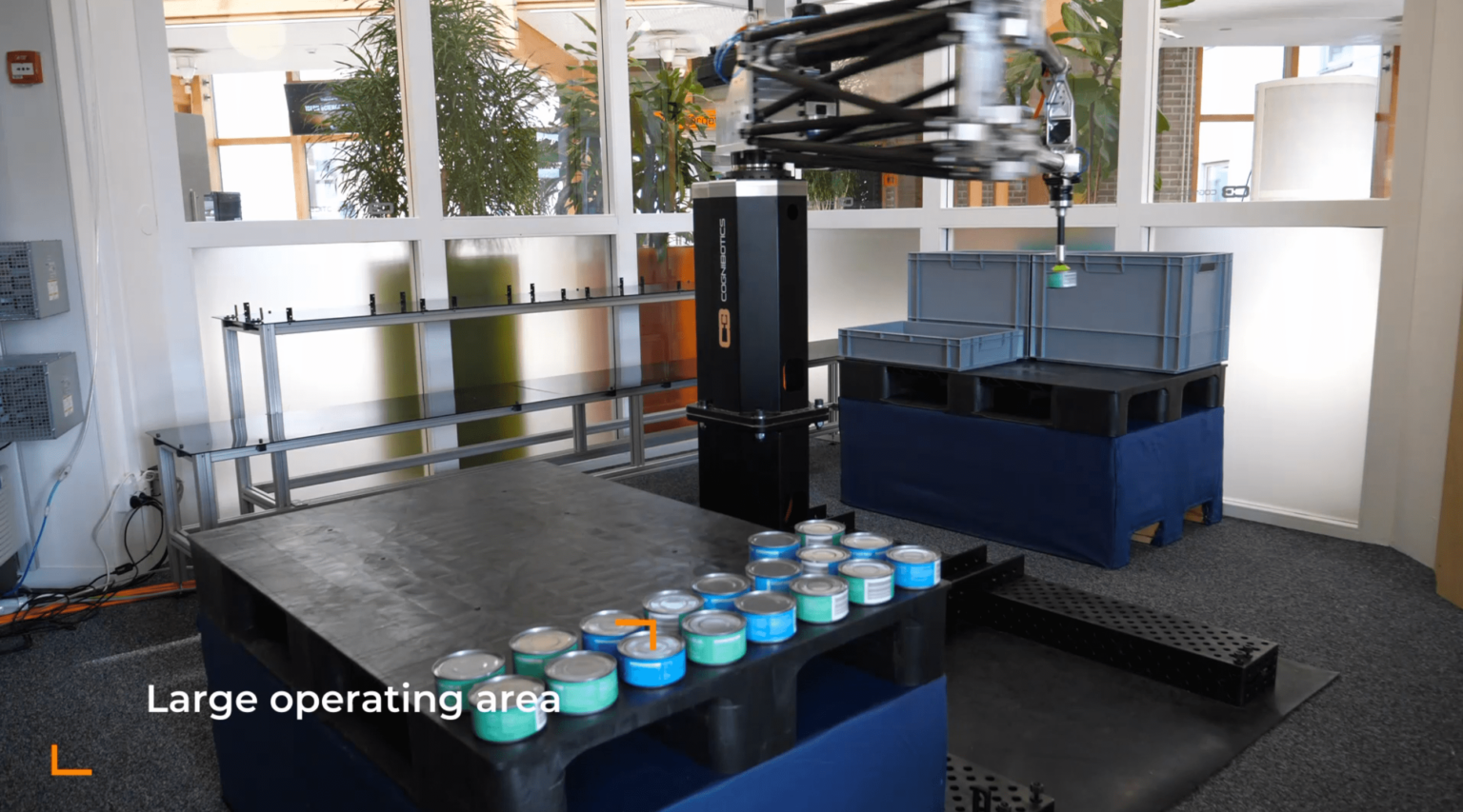

With an active work area of 10 sqm you can build highly integrated and efficient picking stations. You can easily combine multiple pick and drop locations with multiple action stations to get the job done without the need to add more robots or serialize your work tasks. Let the robot complete the picking, placing and packing all in one integrated process!

Use the high speed of the robot to maximize the order throughput and sorting speed in your warehouse. Make sure you can take the full advantage of the capacity of your warehouse infrastructure and generate maximum customer value at the same time by getting the orders out the door as fast as possible.

The HKM robot can handle any item up to 7,5 kg with superior speed. This means you can handle the vast majority of articles and small packages in your warehouse.