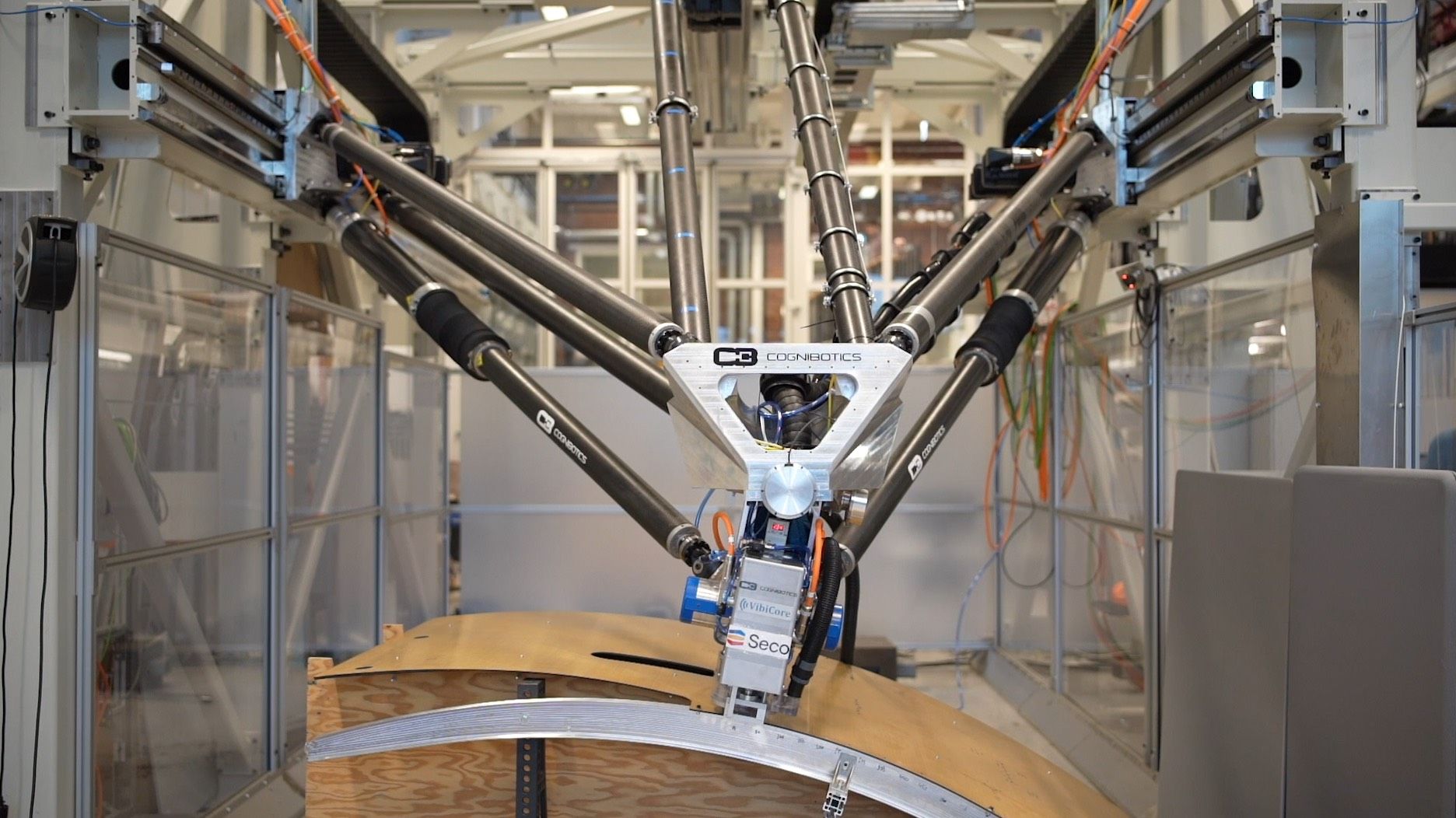

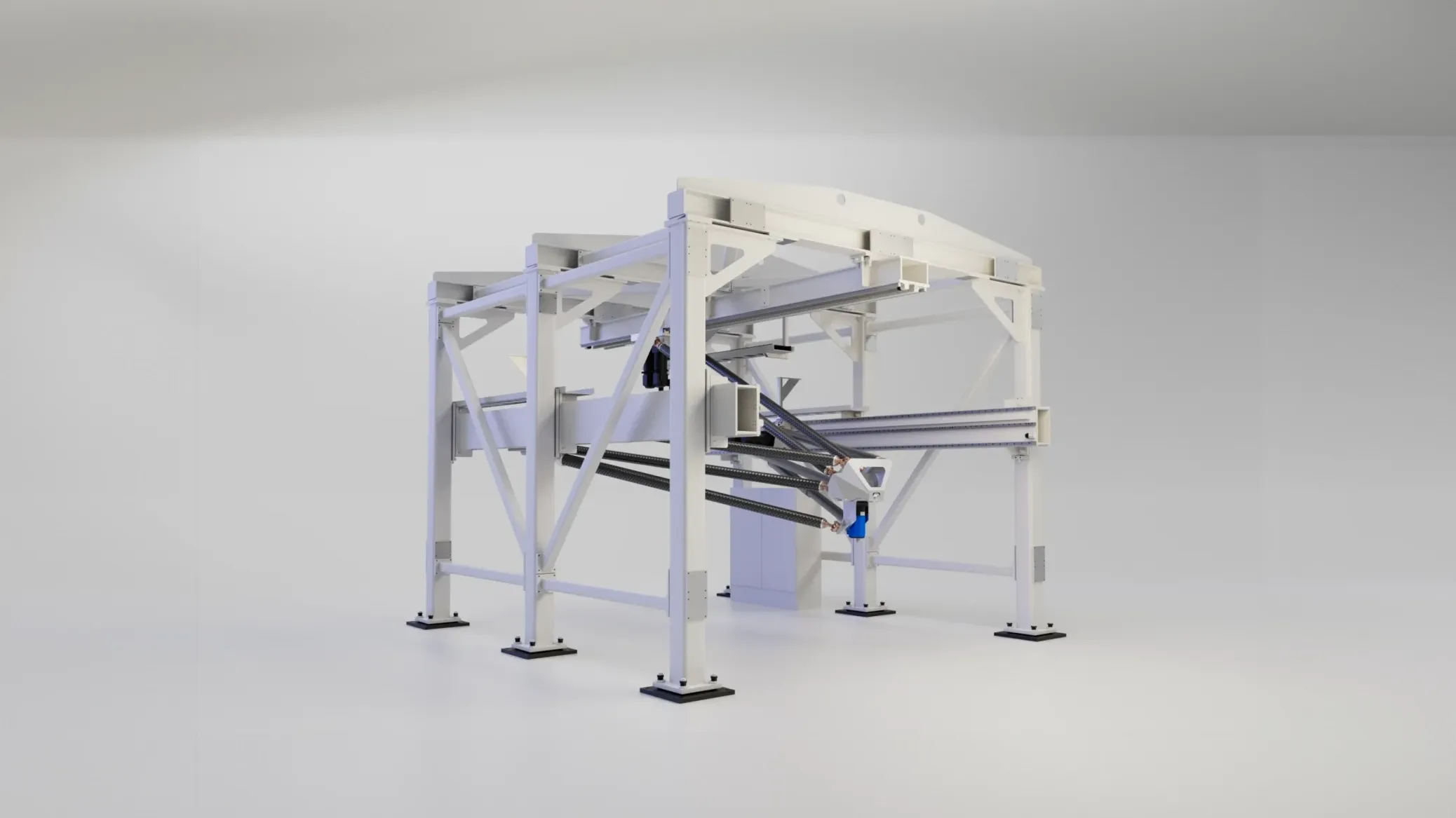

The robot achieves superior rigidity, accuracy and dynamic motion performance due to the lightweight eight-link SigmaTau parallel kinematic concept.

The solution provides a high-level of flexibility and can integrated with other production equipment, be installed on a regular industrial building foundation and can even be reconfigured and moved after initial deployment.

Stiffness and rigidity makes it ideal for handling process forces

For Hybrid manufacturing setups with need to change end effectors frequently

Lightweight high-dynamic mechanics

For tolerances down to 0.05mm

Achieving Extraordinary Surface Finishing with SigmaTau ST 3000 Robots

Near net shape prints, post-processing and machining in the same setup

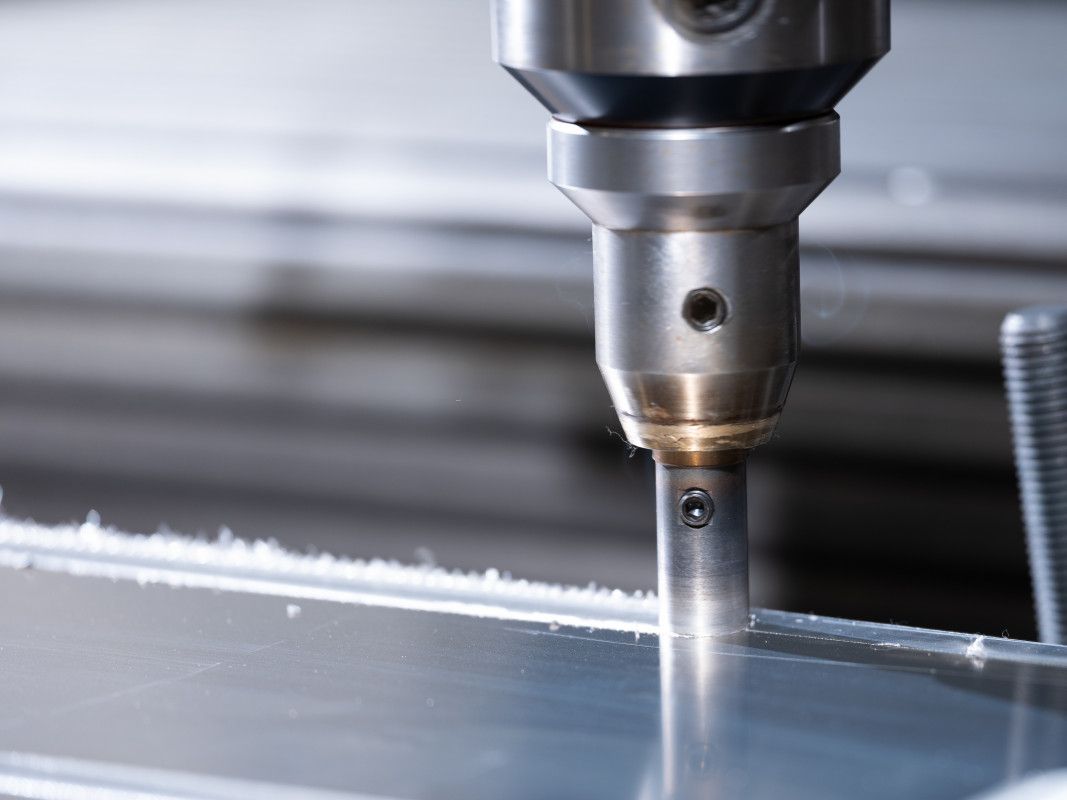

The process facilitates dry drilling, allowing for the creation of holes in a single setup

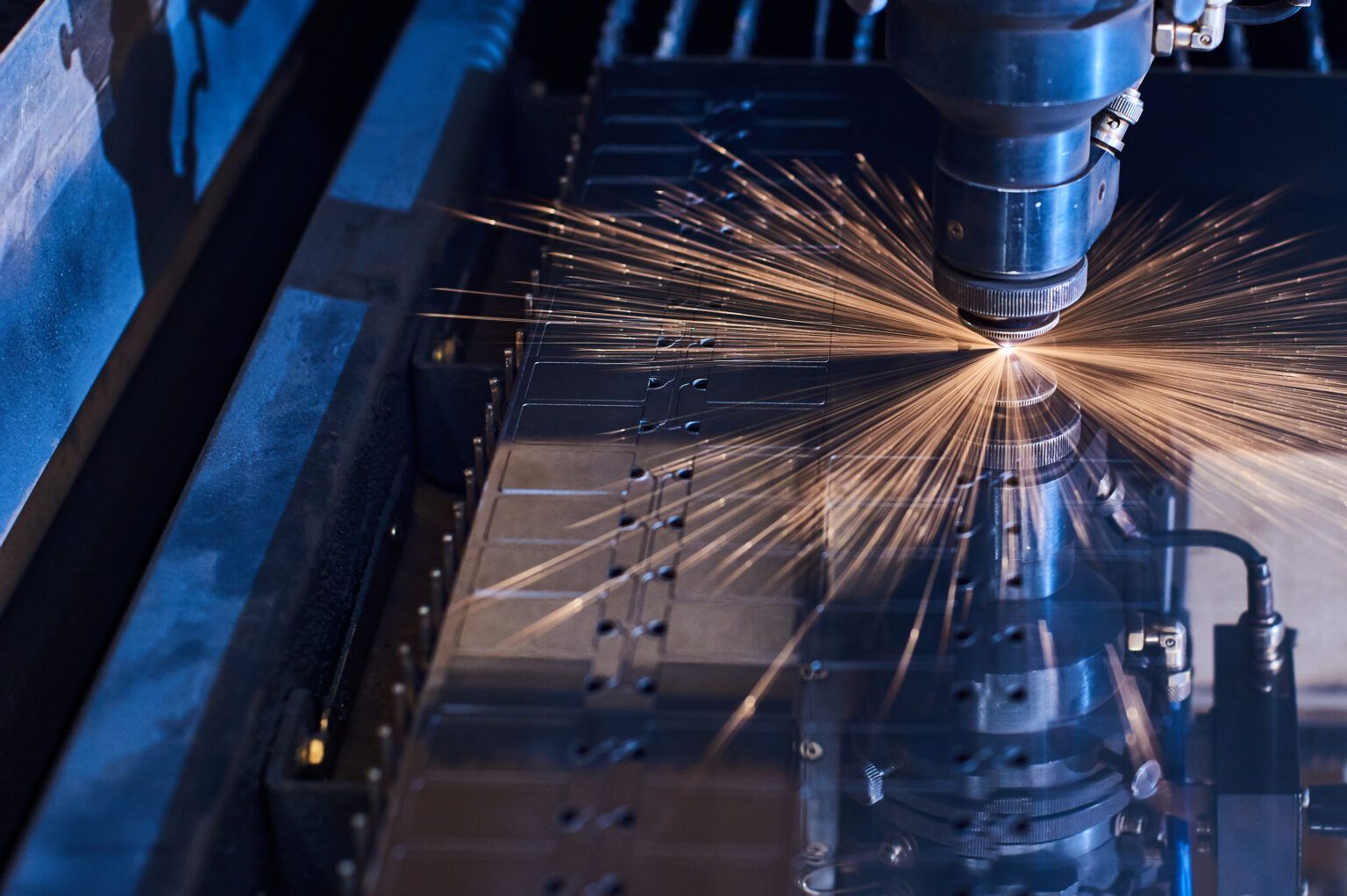

High dynamic characteristics enable precise, high-speed cutting and welding of large-scale parts.

Motion and force control ensure precise welding on freeform surfaces, where high dynamics and stiffness are crucial.

The SigmaTau robot can be installed around an assembly line to perform precision processes such as machining in-line, along with the production flow.

This gives far higher efficiency than a CNC machine tool which would require its dedicated floor space and often a separate robot for machine tending to perform the same operations at a slower pace. Due to its high installation flexibility, a SigmaTau robot can even be moved and reconfigured for different setups.

The lightweight mechanics allows high dynamic motions with 2G accelerations to minimize cycle times.

Suitable parts include large weldments or castings that require finishing machining (such as milling, drilling, tapping) or high-speed laser processing.

Robots based on parallel kinematics bridges the gap between CNC machine tools and traditional arm robots. Their parallel load-bearing structure enables them to absorb high process loads and maintain a high rigidity and precision. Further weight reduction increases their speed and minimizes intrinsic inertia.

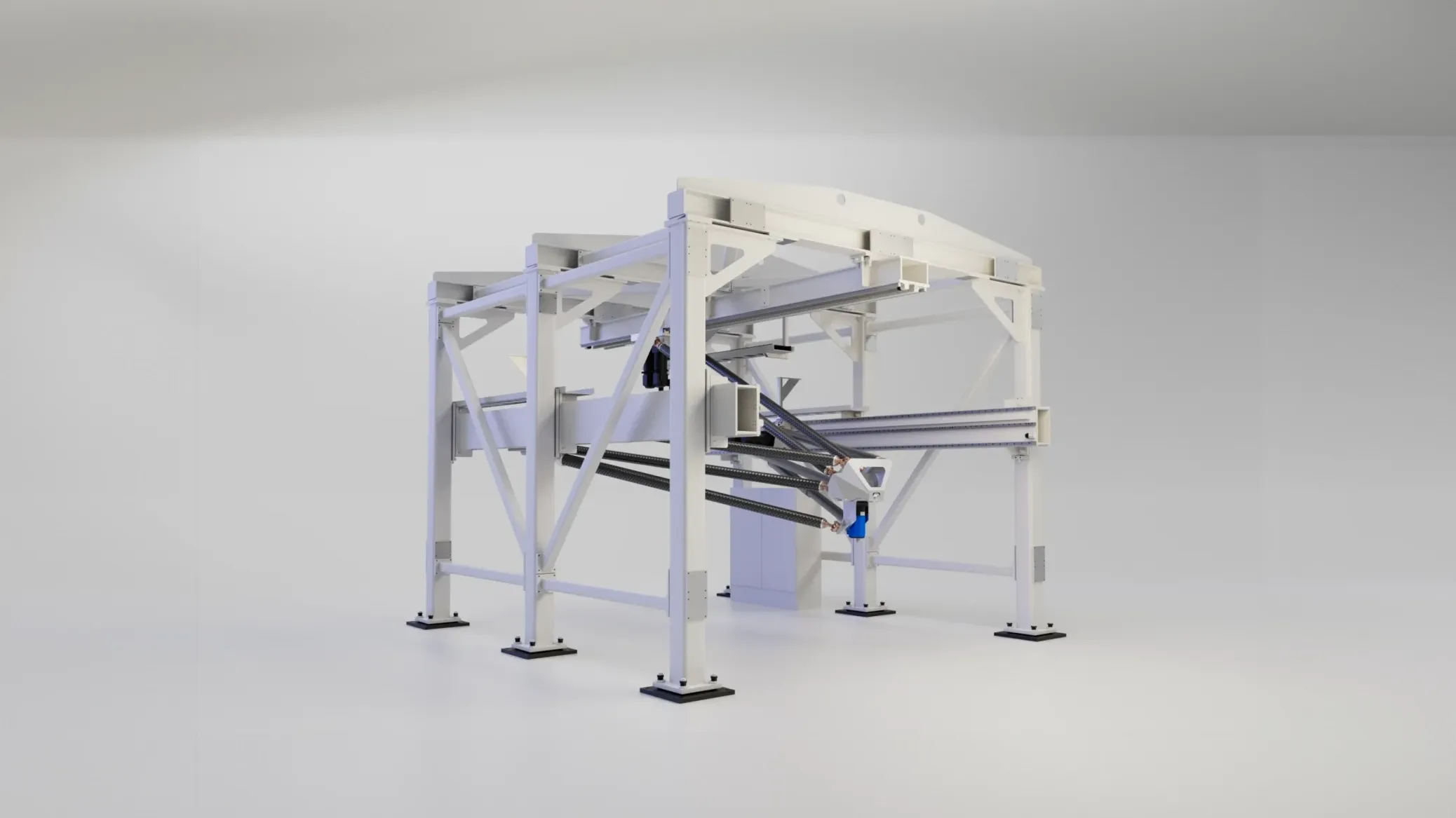

The SigmaTau arm system is mounted on three linear motion rails on a customized machine frame. The flexible mechanical structure has minimal requirements on relative alignment, which allows for a quick and easy assembly process followed by a kinematic calibration.

The robot consists of a 5 or 6 axis wrist mechanism, three guiding blocks, and eight links, which are arranged to provide a lightweight but still rigid manipulation.

The workspace can be customized by selecting different link lengths while the guiding blocks remain the same design regardless of workspace size but are available for different loads and rigidity needs. They are designed with Finite Element topology optimization to further reduce weight without compromising rigidity.

SigmaTau is a versatile robot with a broad range of capabilities. Suitable for shops with frequently changing production needs, looking to utilize their equipment to a maximum. Applications include milling, drilling, tapping, welding, additive manufacturing, along other processes.

Configured with a 6th axis addon around the spindle, the robot can be utilized for both 5-axis machining and 6-axis processes, such as welding, with a quick tool attachment without impacting the milling spindle.

The flexibility to change between processes simplifies the planning and maximizes equipment utilization.

Integrators and machine builders can use the SigmaTau modular system to efficiently design and deploy high performing solutions for advanced manufacturing.

For manufacturing companies dealing with large parts, we can provide assessments, demonstrations, prototype productions.

We can also work together with your local integrators or connect you with our current partners to provide process expertise.

20x less moving mass

170 m/min speed

2,5 g acceleration

5 μm repeatability

40 μm tool path accuracy