With accurate robots, you can increase productivity and cost-effectiveness by minimizing the time spent on costly manual adjustments during program deployment and sensor integration. Moreover, accuracy makes the robot capable of achieving finer motion tolerances, which enables the utilization of robots in demanding processes.

Our CogniCal calibration solution supports both factory and field calibration of robots and cells, including multiple robots and external axes, providing accuracy for every robot, everywhere!

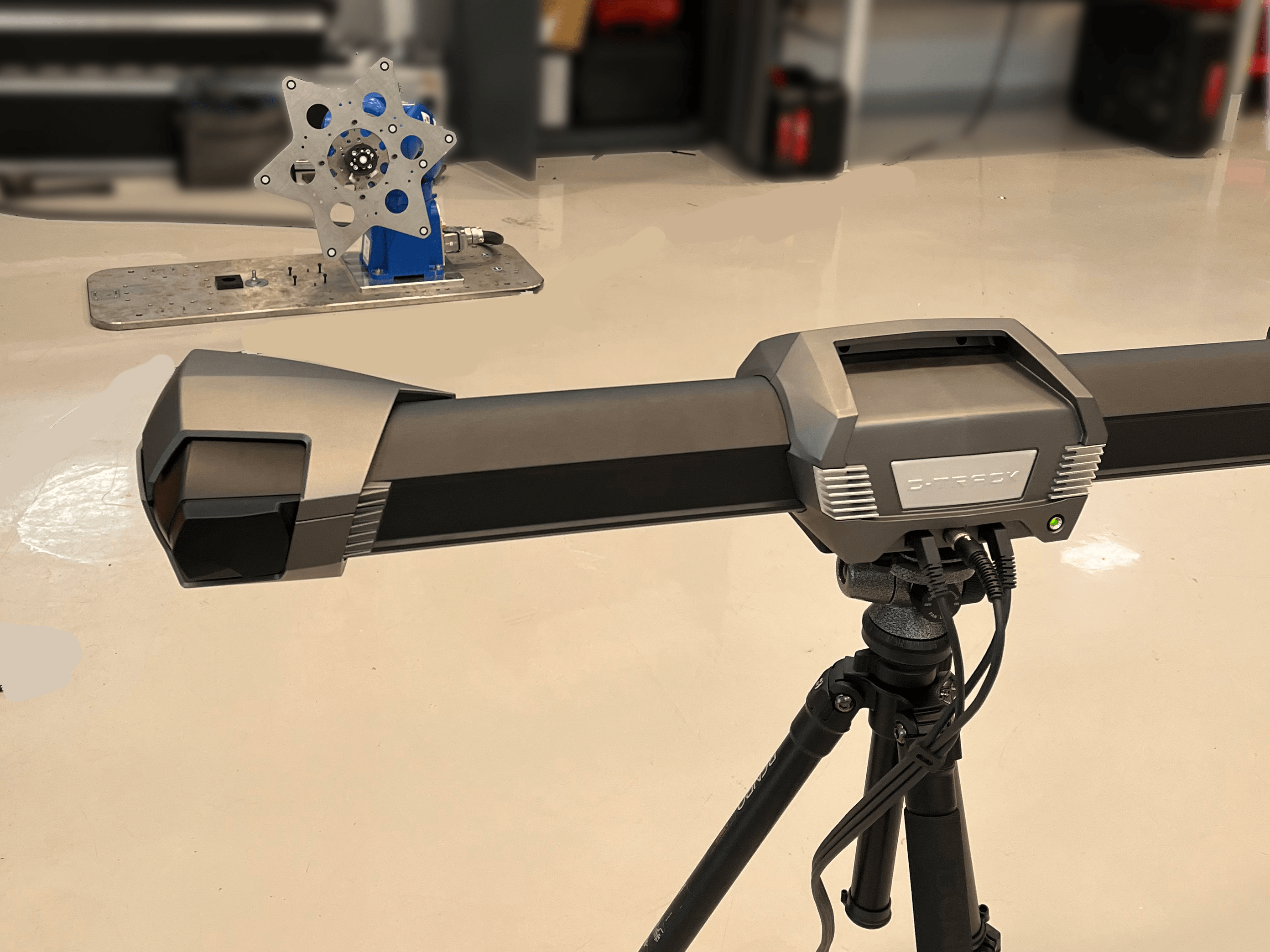

Cognibotics calibration package includes equipment and software to efficiently perform elasto-kinematic calibration of industrial robots of all kinds, also including external axes.

Package options:

CogniCal with C-track for calibration of robot and external axes

CogniCal for usage with third-party metrology systems, e.g. laser trackers

Also available as service for a limited amount of calibrations.

Unlock the full capabilities of your robot mechanics with our elasto-kinematic and dynamic performance-enhancing modules.

Requiring full motion kernel access, this setup gives best-in-class absolute and path accuracy also under high speeds and various loads.

Cognibotics accuracy add-on uses a parameter key from Cognibotics calibration to accomplish robot accuracy for all major robot brands without special interface requirements. Three versions are available:

Post processor; applicable for invariable robot programs

Online processor; applicable for programs relying on position data collected at runtime

Module for integration with application software

Accurate robots are easier to integrate and deploy which speeds up the installation and makes the process more predictable.

Accuracy is important when creating paths or sharing position information with other systems

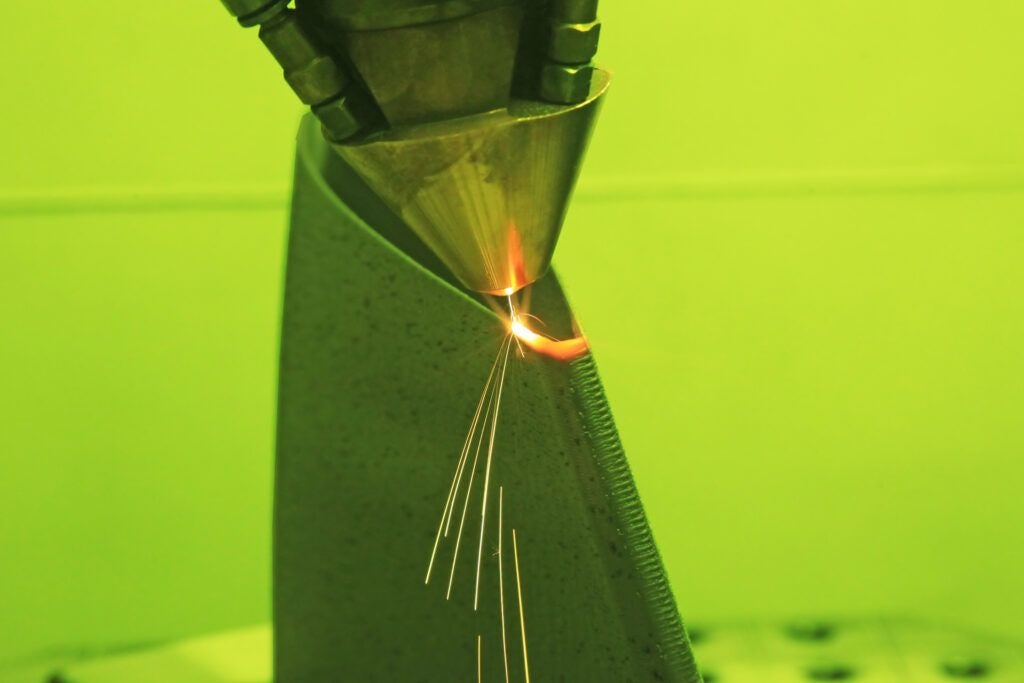

In order to meet the needs of future production, it is essential to have manufacturing equipment that is both cost-effective and flexible.

The answer lies in utilizing highly accurate robots as multi-process machines.

Operational reliability is essential in complex automated production, it minimizes downtime and enables continuous production.

While industrial robots are renowned for their reliability, it is important to recognize that they are not immune to wear and incidents.

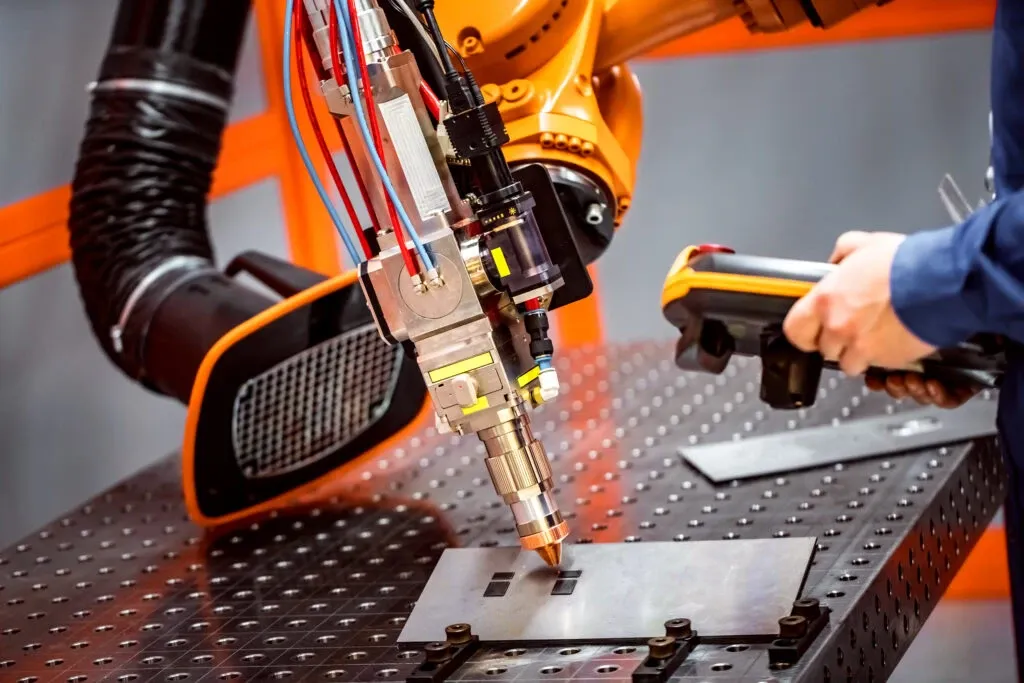

The affordability of robots, in contrast to specialized machines, presents a strong motivation for processes that require a flexible and extensive workspace. However, the overall accuracy of the robot system, which includes positioners and linear tracks, is commonly impeded by the mechanical structure and its lack of stiffness, thus acting as a significant constraint.

To utilize robots for cost-effective and flexible production, even for small batch sizes, it is critical to attain the required level of accuracy.

Identifying and compensating for mechanical imperfections in the system, and elasticities throughout the robot structure is crucial.

Robot accuracy closes the bridge between the real and the digital world. Modern tools give great possibilities to design and test robot cells digitally, typically using a digital representation of a nominal robot.

For commissioning on the real setup to work smoothly, the real robot should behave like its twin, which is only the case if the robot is accurate.

With accurate robots, process programming results in generally applicable programs, which can be used on various robot individuals and cells without major touch up.

Despite regular robot maintenance, it is hard to detect problems before they occur and cause more costly production failures. By integrating robot diagnostics in the production cell, robot component issues can be detected before they affect the process performance.

Issues requiring service or repair risk modifying the robot motion, leading to time-consuming program adaptations. With Cognibotics robot recovery tool Flexclamp, the deviations are identified and automatically mitigated. Built-in reliability for consistent high-quality production.

Articulated robots are typically inaccurate due to mechanical imperfections combined with a structure where small errors add up, and a control system using a very simplified model of a robot as default.

The unique competence of Cognibotics lies in the ability to create superior mathematical models to describe the imperfections and deflections in robot mechanics.

Those models are a much better representation of the real robot and are usable within the real-time cycles of a robot controller.