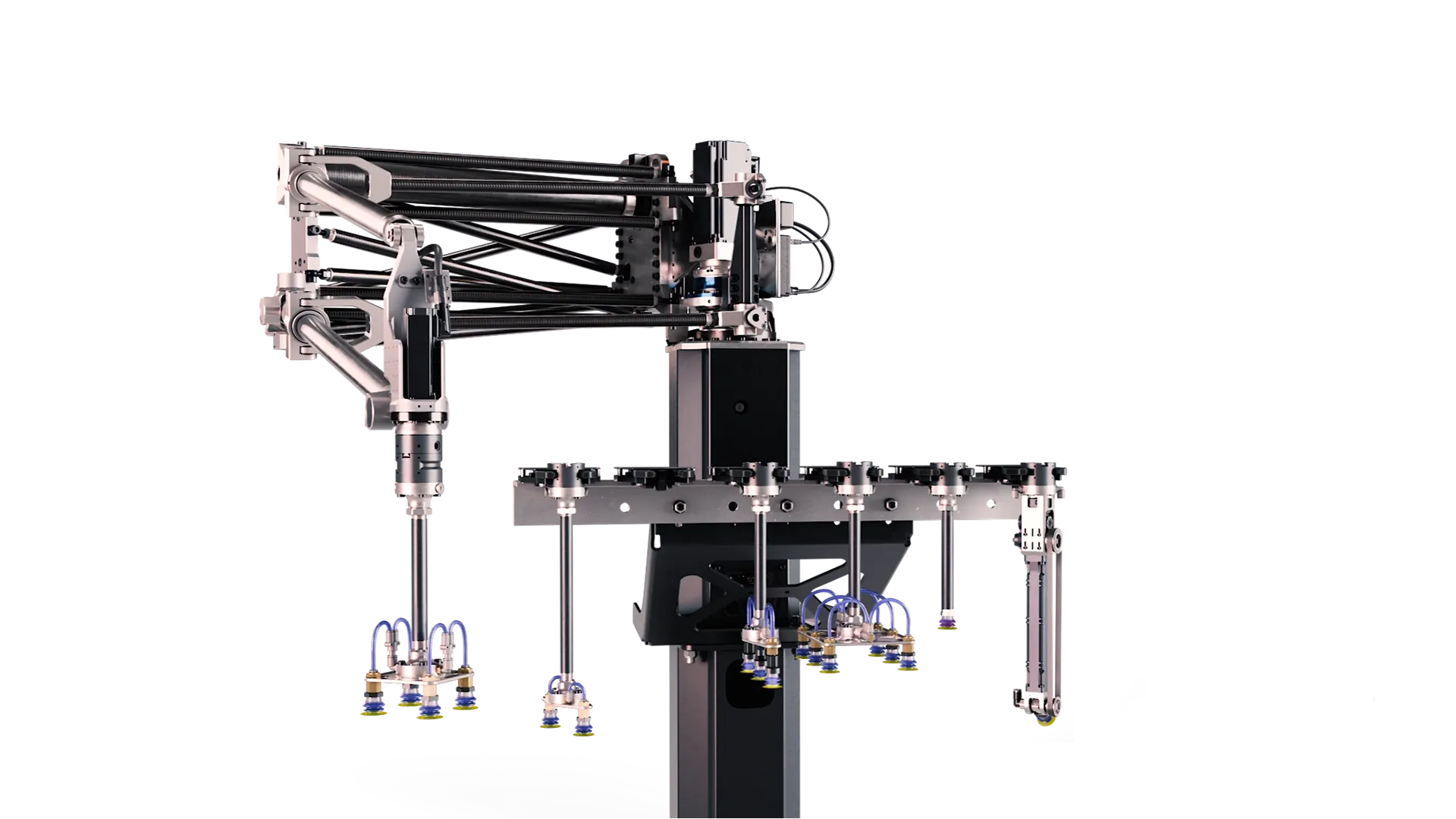

Cognibotics enhances the productivity of warehouse automation through a scalable and flexible automated picking system with superior reach, speed, and range.

Short cycle time, above 2000 picks per hour

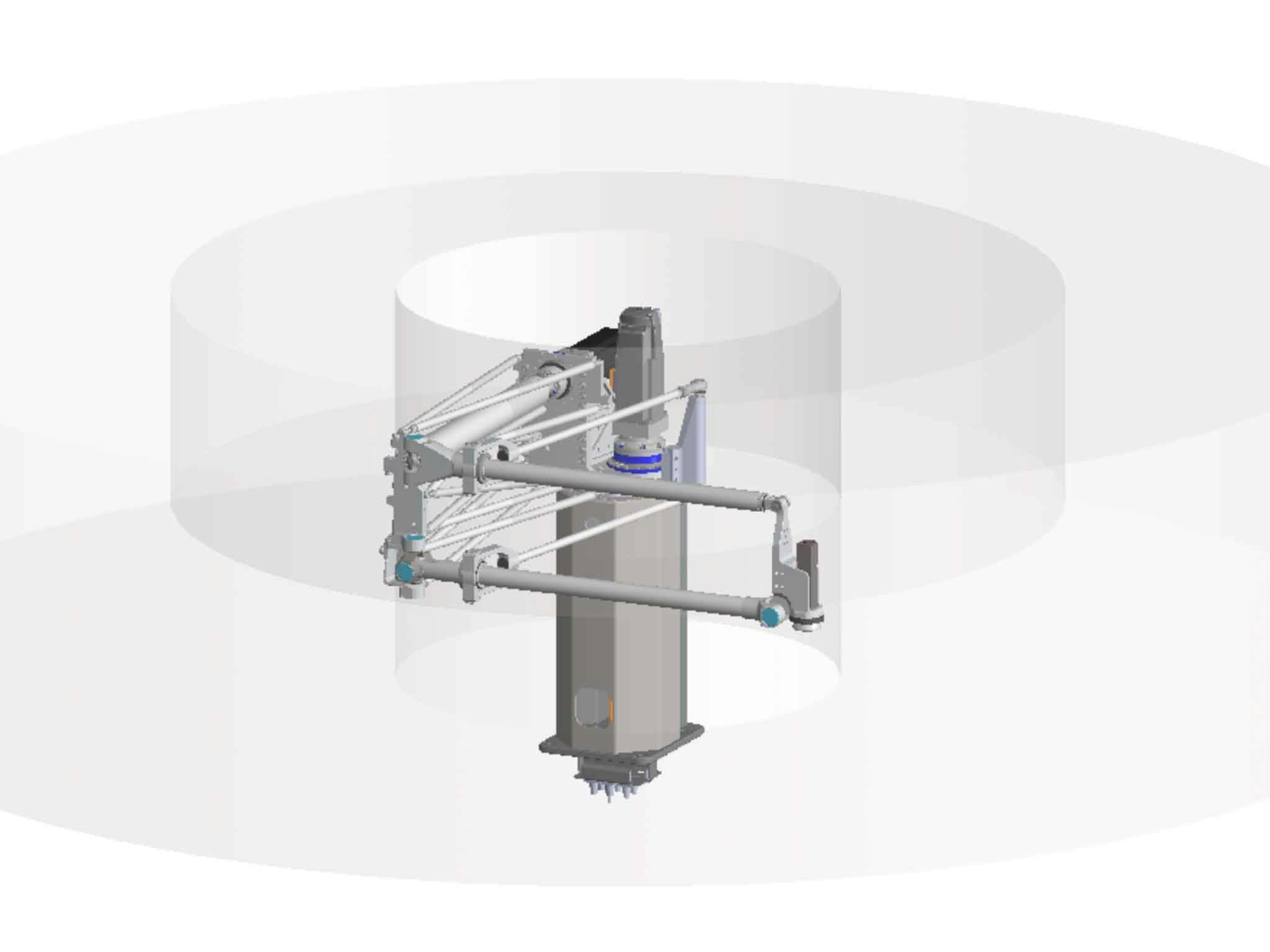

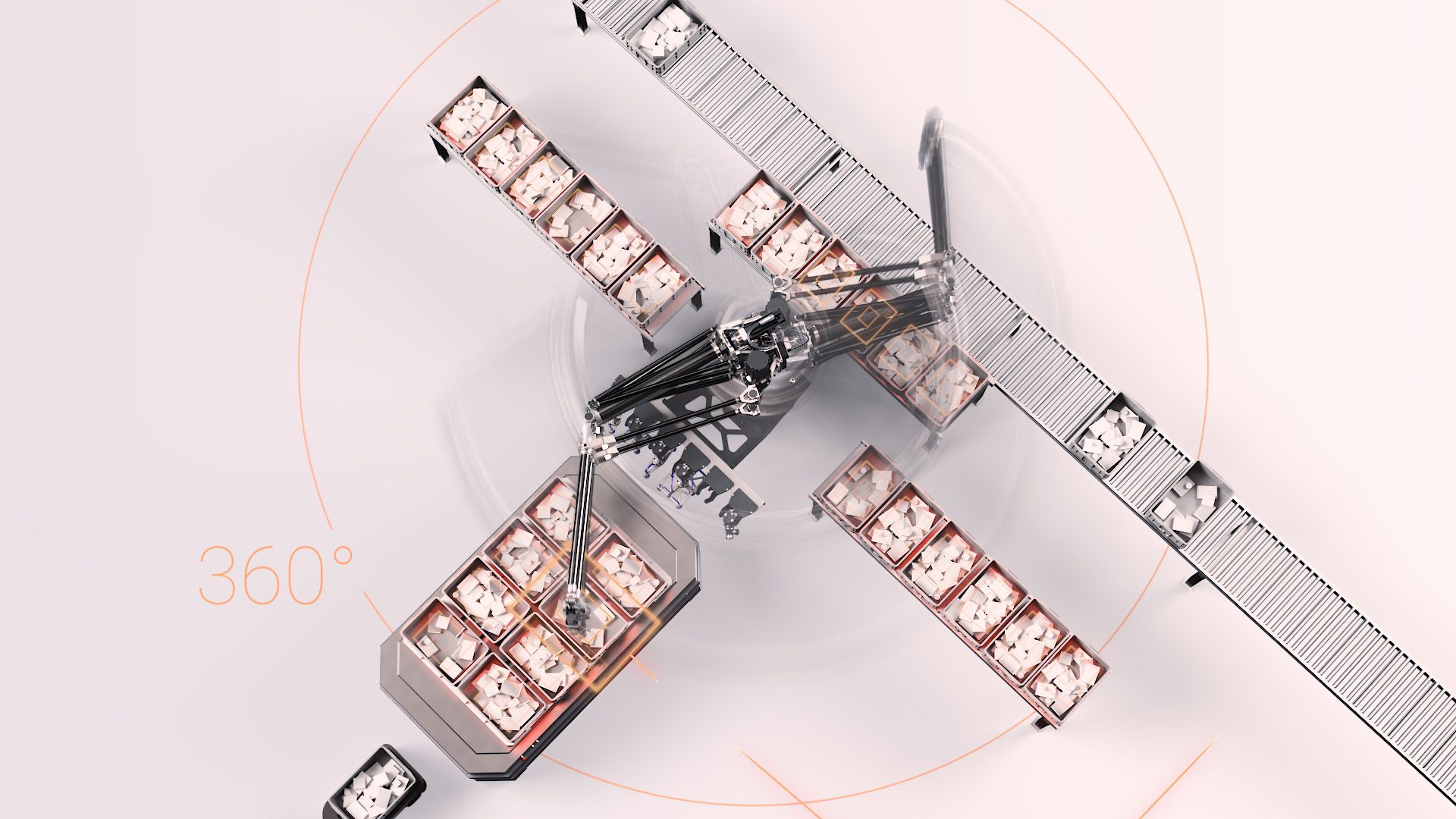

1.8m reach over 360 degrees. Corresponds to 6 EU pallets

Future proof the range of customer and articles

Perfect fit for compact production lines

Its extensive reach enables it to handle record-setting number of bins, enhancing productivity within the MovU escala bin shuttle system.

One HKM1800 robot significantly boosts productivity by managing the workload of two traditional picking stations.

Cognibotics HKM1800 robot is set to deliver a new level of productivity and simplicity.

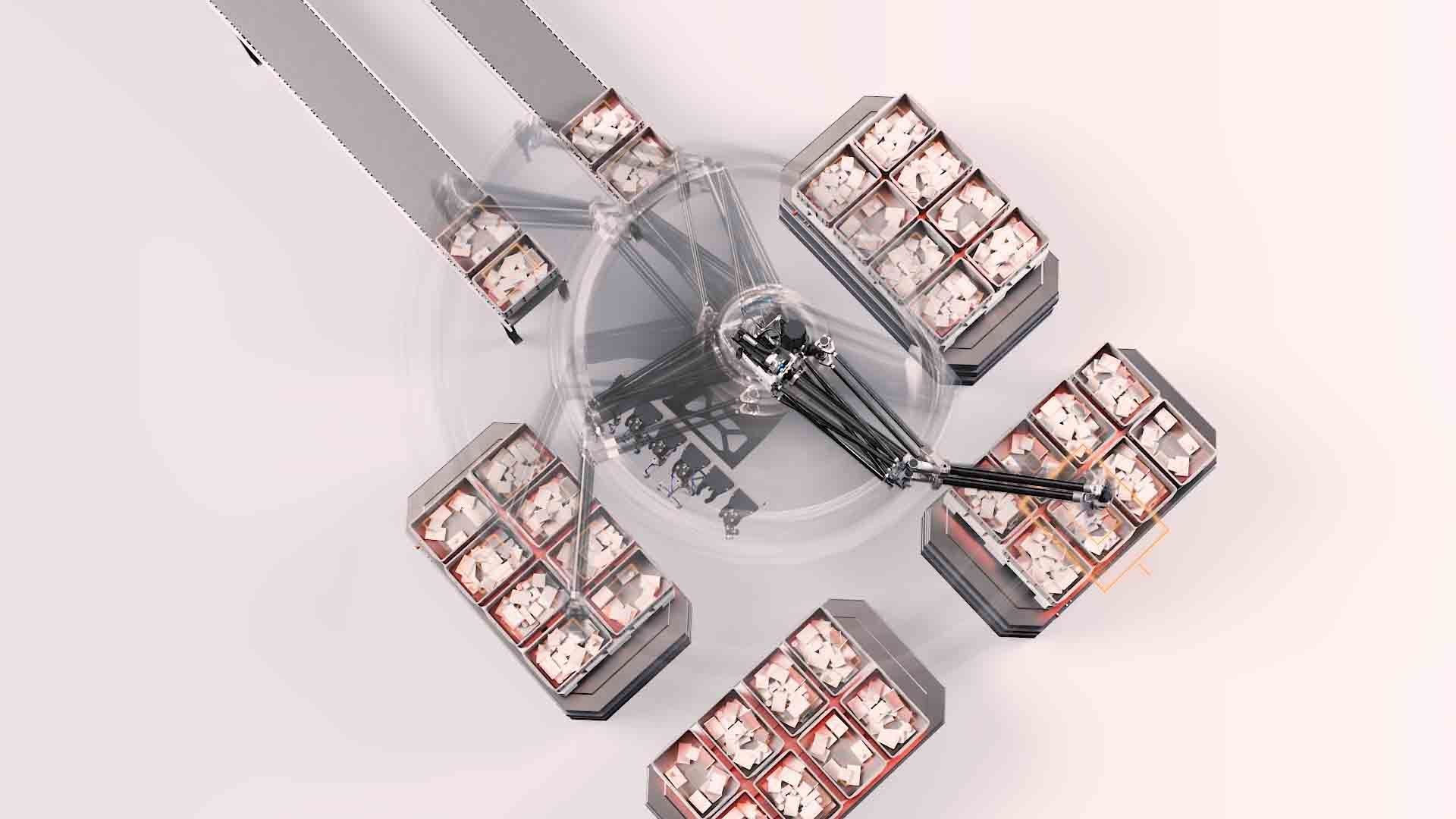

The HKM1800 enables new opportunities for robotized material handling in warehouse automation when the distances are longer or include several pick-and-place positions over a large surface.

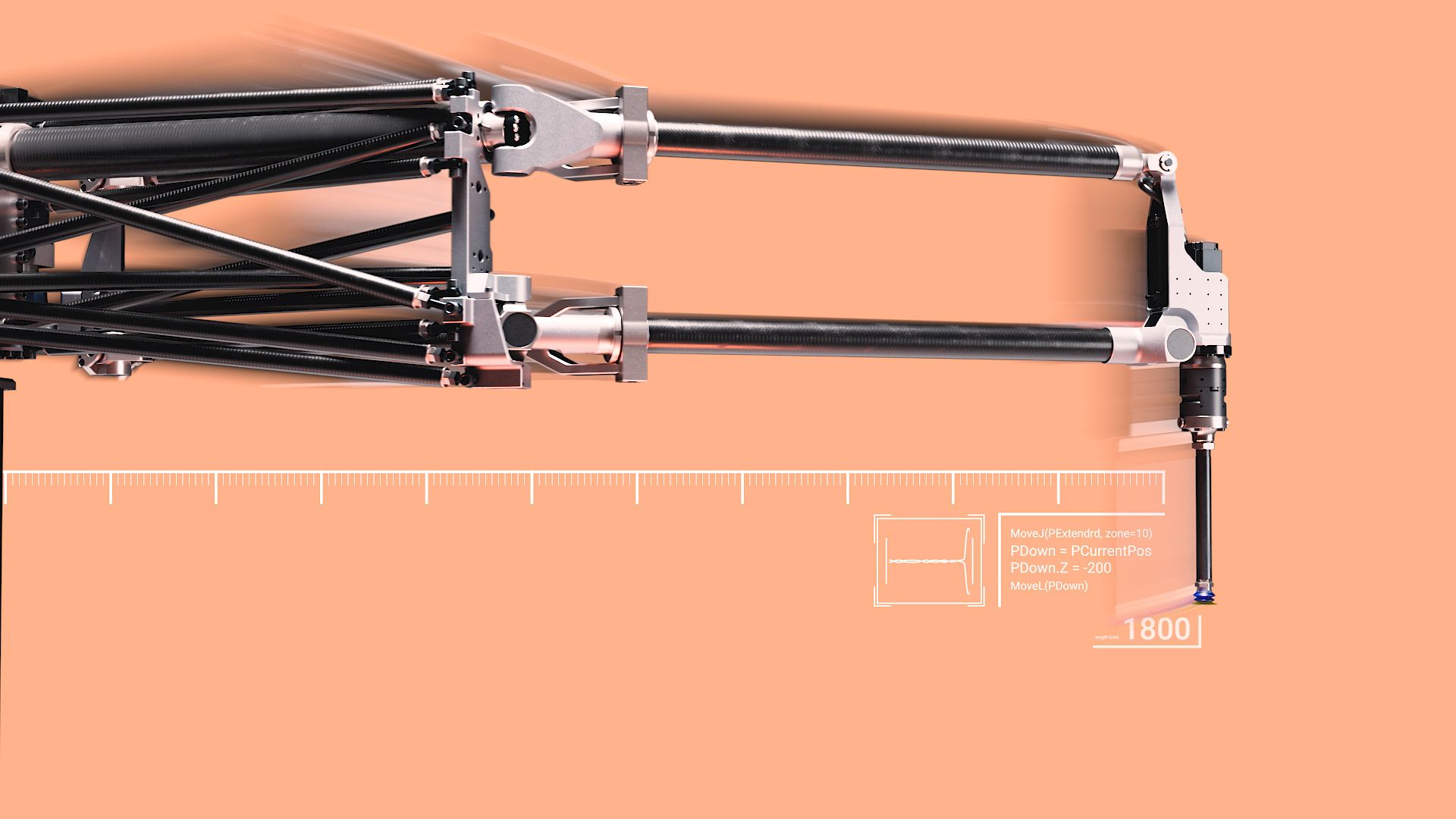

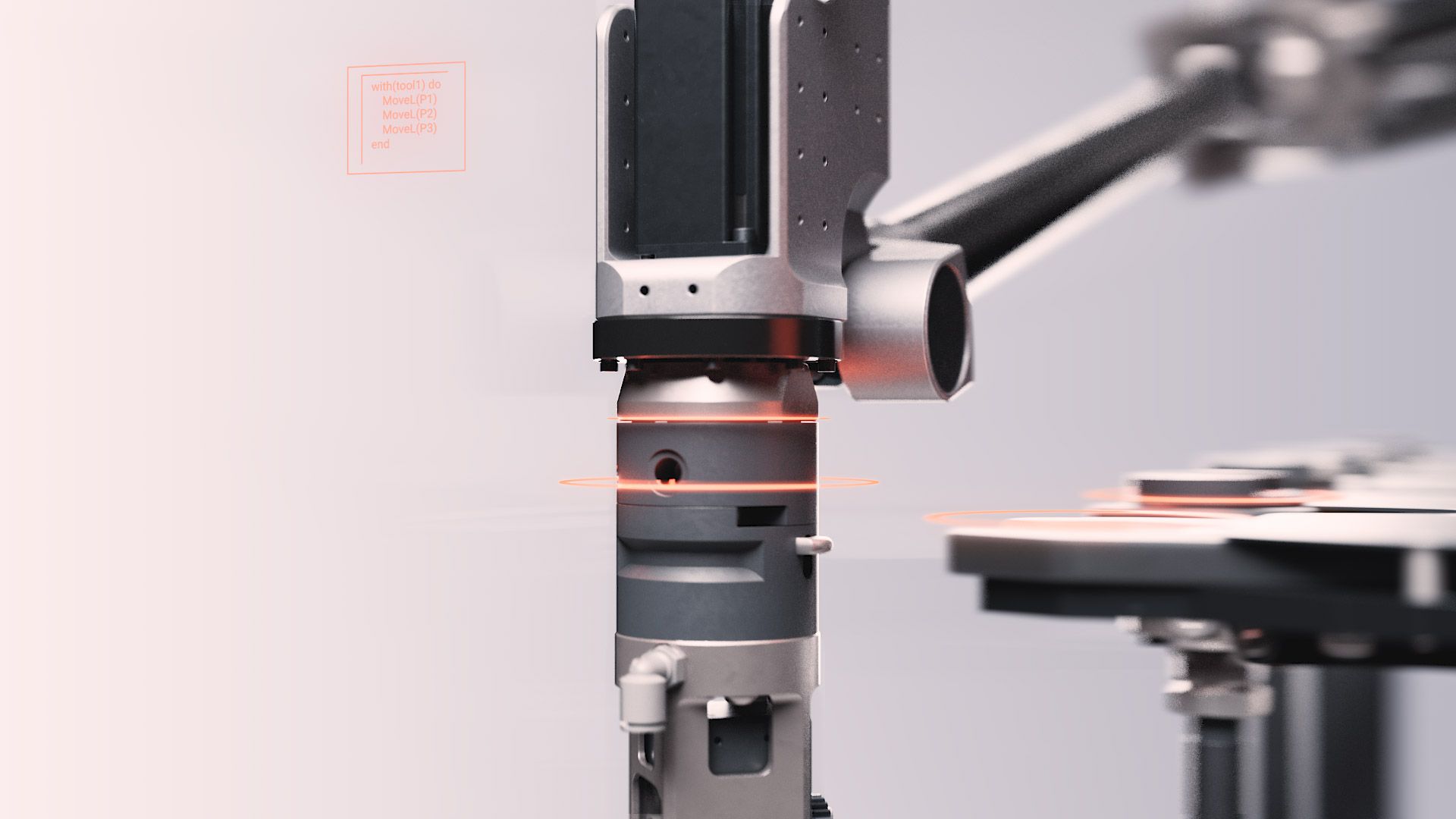

Built on low-weight, high-performance material and configured to have extremely little moving mass, enabling top performance while minimizing energy consumption.

Hybrid kinematics combines the advantages of both serial and parallel kinematics. This enables the lowest moving masses and shortest possible cycle time over large circular work areas.

The super light robot arm system enables next level speed at a low energy consumption, even along the outer edges of the working space.

The HKM is meticulously engineered to optimize coverage while minimizing floor space requirements. This design not only reduces the footprint, allowing for more compact production lines, but also empowers the robot to operate efficiently upstream and downstream of material feeds. Additionally, it enables dynamic tracking of moving objects for seamless processing.

The workspace of HKM1800 covers up to 6 EU pallets or 10 square meters with an impressive z-stroke of close to 1 m.

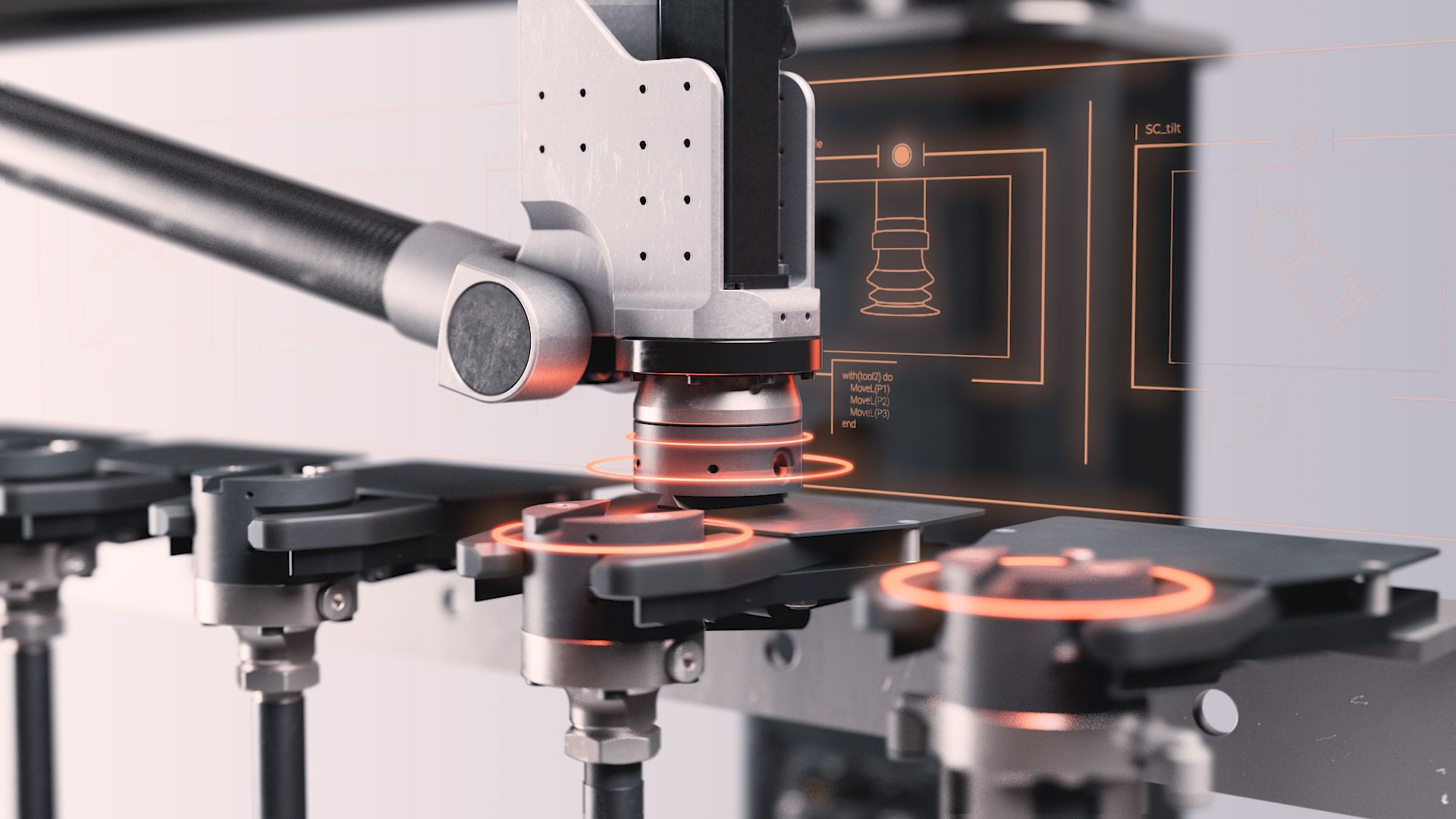

An efficient tool-changing system enables the robot to swiftly switch between different tools, facilitating the handling of various materials and products with precision and efficiency.

The reach and speed of the HKM1800 make it a perfect operator for the most intensive kitting operation.

A range capability and adaptability to handle different items, materials, form stabilities, sizes and weights.

Use the right tool for any items: capable of picking any item up 7.5 kg.

The robot support HTML-based programming using open standardized interfaces and languages. This gives you the freedom to program and control the robot equally well from a PC as well as teach pendant devices.

1800 mm radial reach

2000 mm motions cycle 1.6 sec

Energy efficient

Flexible mounting

Active Motion Stabilization

Unlimited tool rotation

2 kg nominal, 7.5 kg max payload

<125 kg robot weight

Take the chance to learn more about the robot and how it can support your automation needs.