The new version includes hardware and software improvements that will increase the motion performance and robustness of the robot.

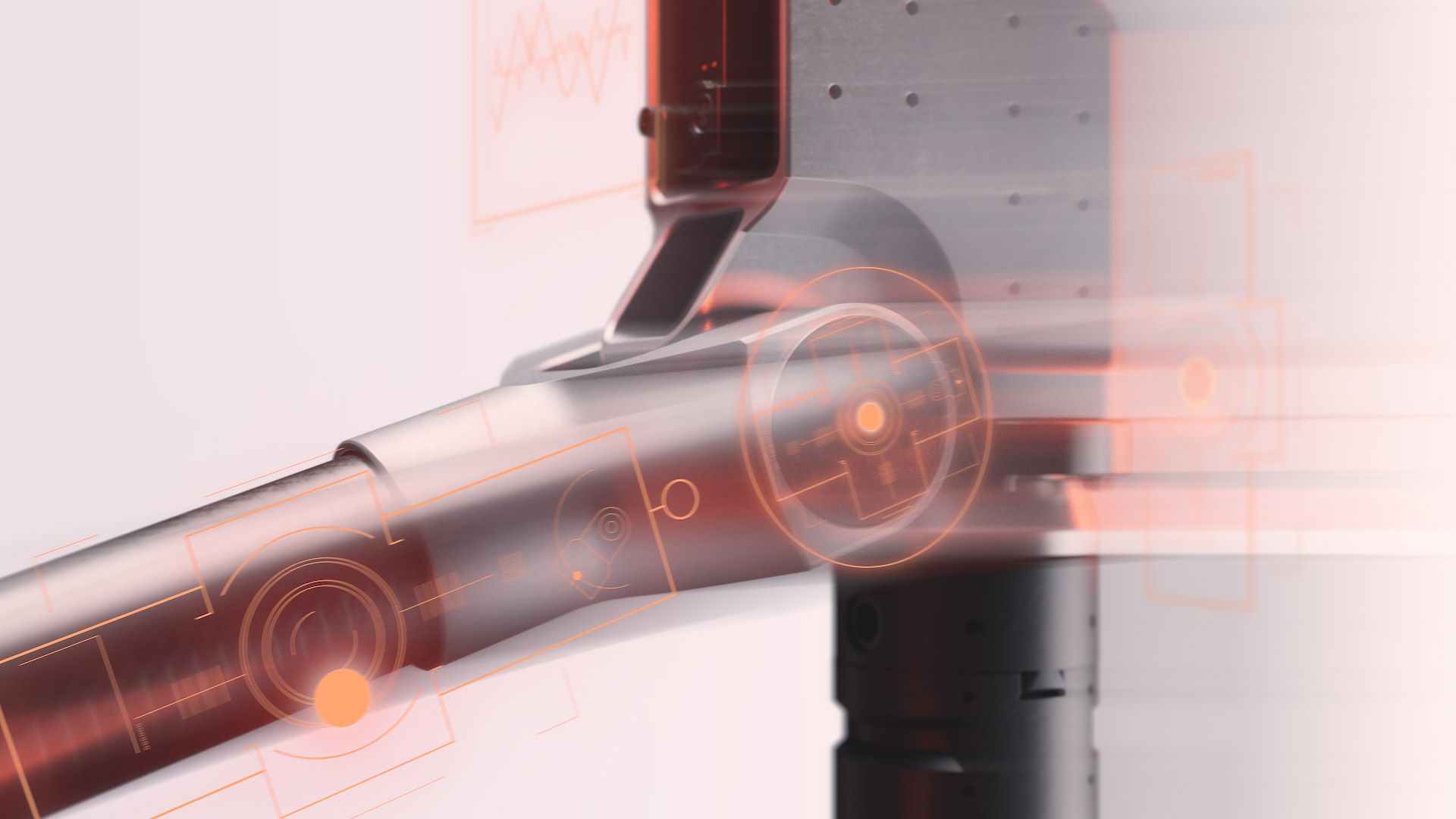

The new Active Motion Stabilization feature compensates for payload variations and deviations via direct motion feedback from the robot wrist to the control system.

This makes picking of items and articles with varying weights smoother and faster.

With an updated wrist axis design the robot tool flange can now rotate freely without any angular limits.

The result is an improved freedom in tool orientation with a neater and more robust tool assembly.

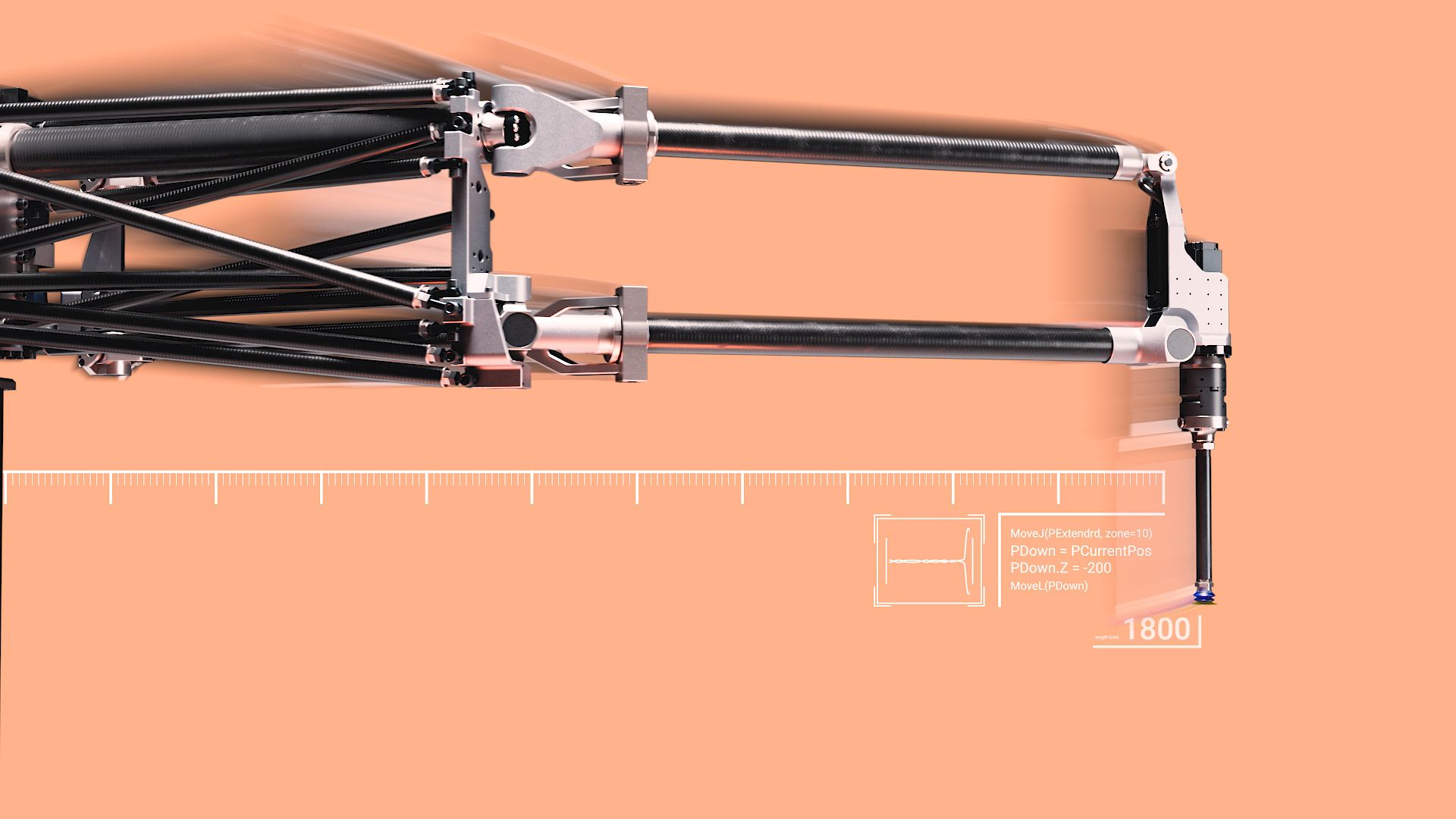

The HKM arm design has been updated to increase the torsional rigidity and the robot can now run 30% faster at maximum payload with maintained motion stability and precision.

This allows for greater utilization of the full workspace of the robot and increase the already fast pick rate.

Cable routing in the HKM robot has been updated to improve installation robustness and mounting flexibility. The new design permits cables to be attached in accordance with installation preferences and increase the protection of the cables.

This minimizes need for maintenance and maximizes slimness of the installed robot.

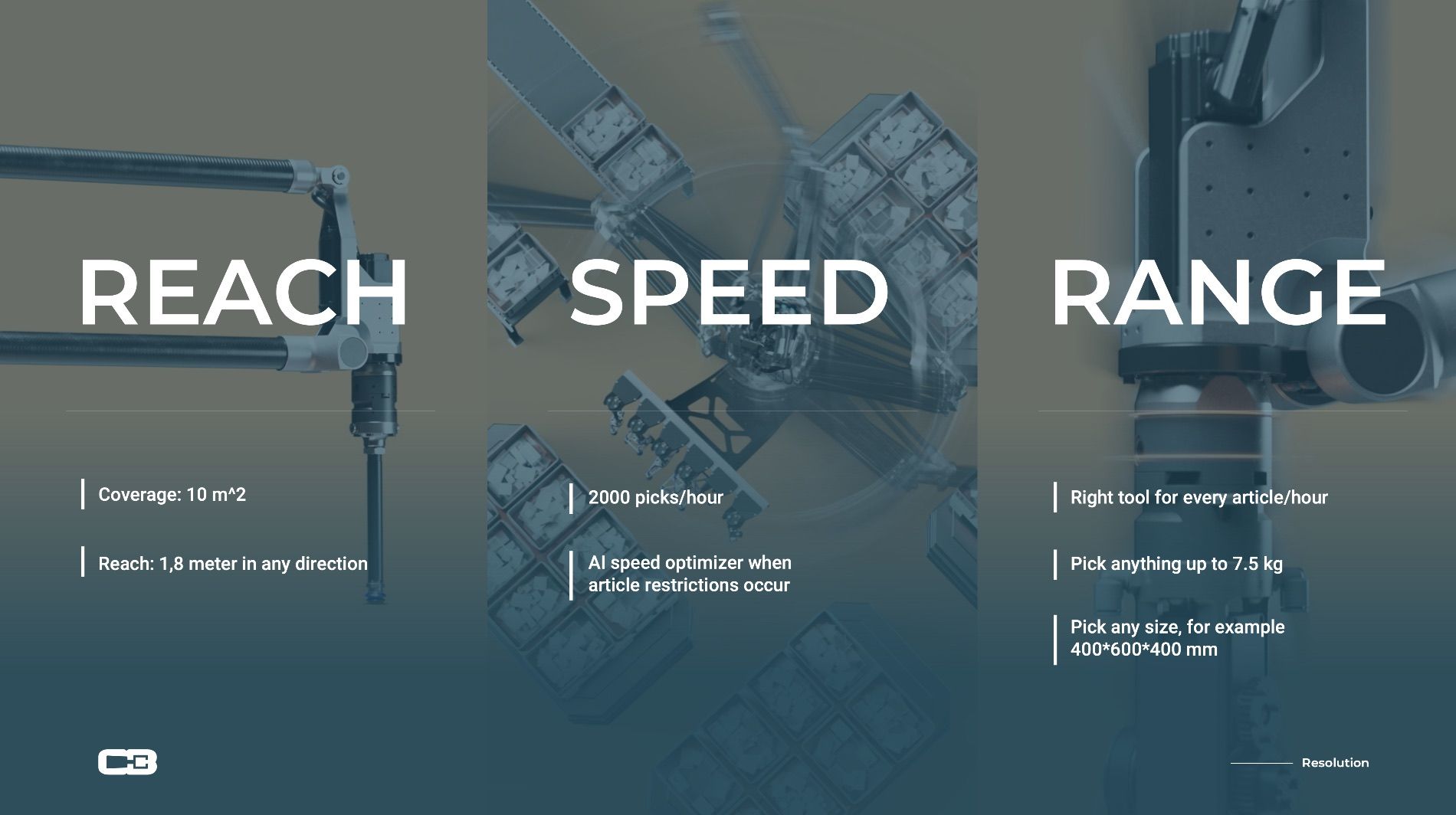

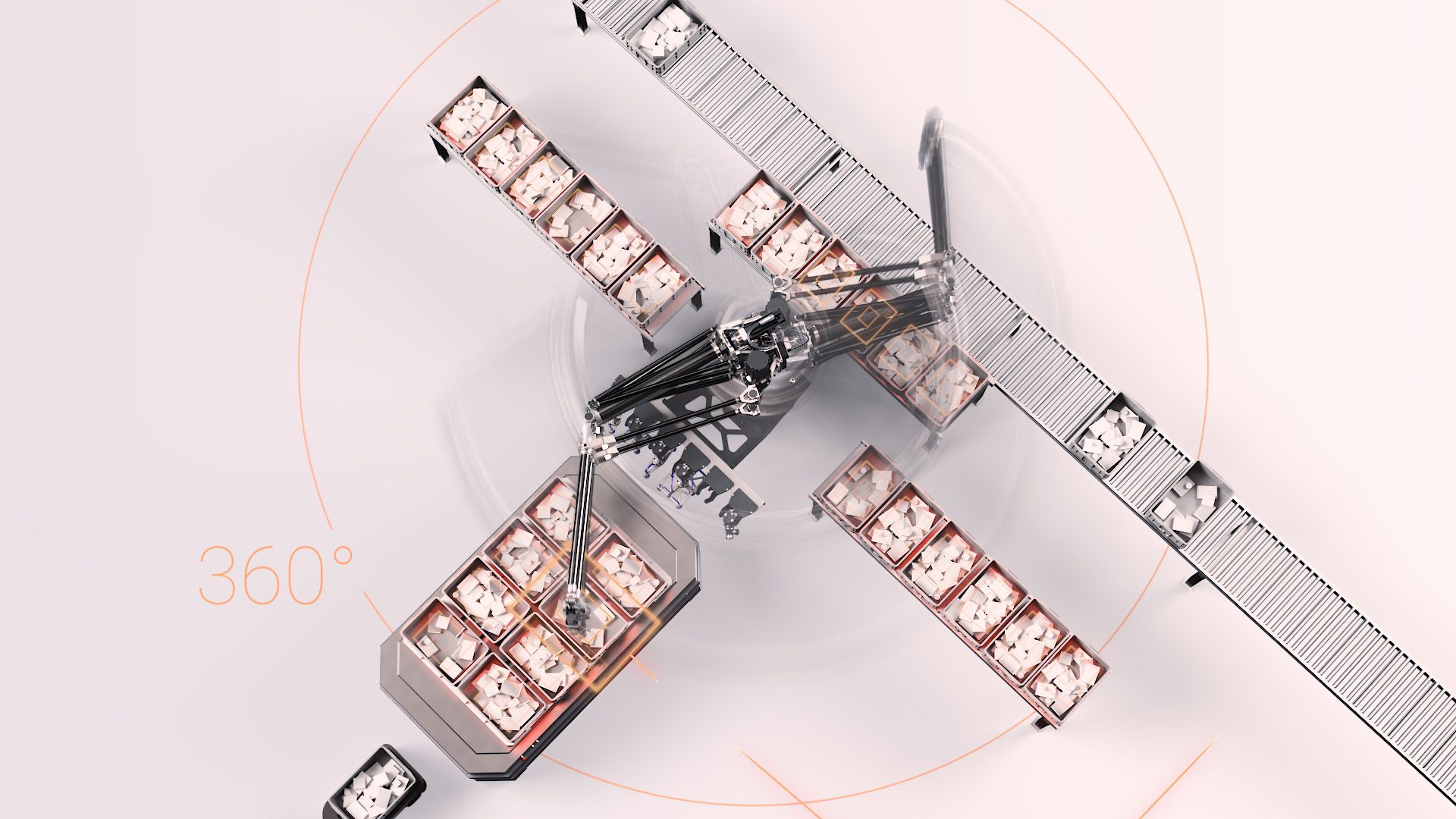

Cognibotics enhances the productivity of warehouse automation through a scalable and flexible automated picking system with superior reach, speed, and range.