Increased productivity in order picking is key to solving the quest for keeping tight delivery schedules with an explosive growth in online shopping and a continuously increasing cost for manual labour.

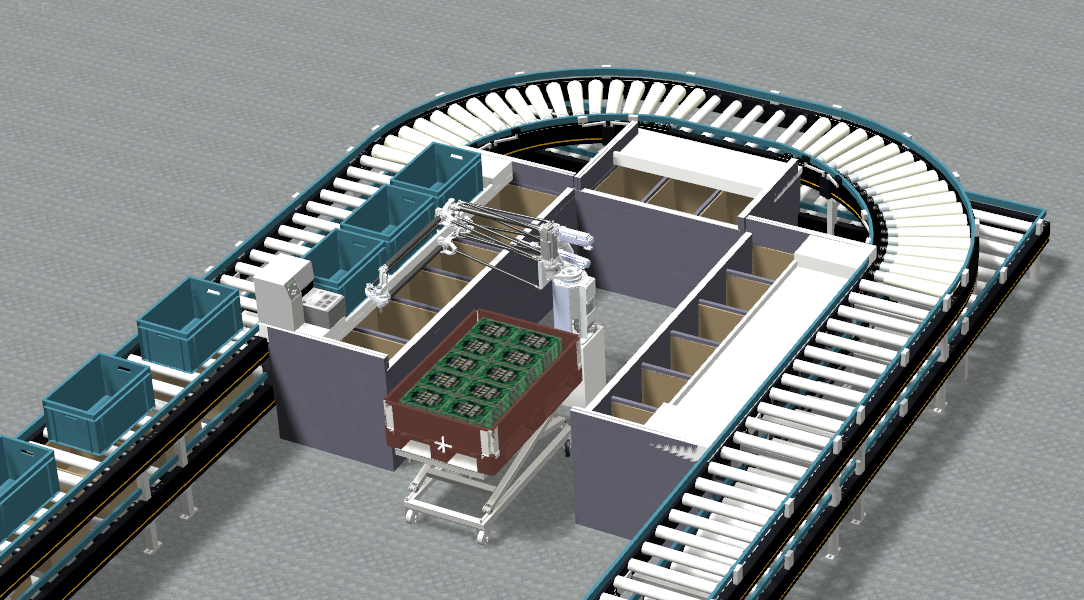

With the new HKM robot enabled order picking system you will get the most out or your warehouse investments:

High speed order picking with up to 1500 picks/hour 24 hours per day.

3-6 times the order throughput per station compared to manual picking

Increased space efficiency with more completed orders per sqm

Reduced total travel time for articles in the warehouse

Possibility to pick directly into multi-option customer packages

Fewer work related injuries

Safe robot-human co-existence

In warehouse management the level of automation is rapidly growing to meet the drastic increase in orders from online stores and retailers. Third party logistics companies as well as in-house warehouses are struggling to keep up with the ever increasing number and types of articles as well as the growing demand for fast or even instant deliveries.

Despite large investments being made into automatic storage and retrieval systems (ASRS) which drastically help organize vast numbers of articles several tasks still remains manual and time consuming. The consequence is both limitations in scalability and a high cost for manning up manual stations at times when employees both look for more challenging work, work regulations are becoming more strict and the need for operations outside office hours is becoming the new norm.

One of the most intense manual tasks is order picking. An activity that means that a person picks item by item, one at a time, to complete a customer order. This is proving to be a task difficult to scale which often becomes a bottle neck for profitable growth. By presenting logistics companies with an option to pick from multiple sources to multiple customer orders in parallell and combine it with a high speed robot you can increase order throughput with 3-6 times/pick station compared to a manual worker. In addition you can operate the station without additional costs around the clock, outside your normal shift hours.

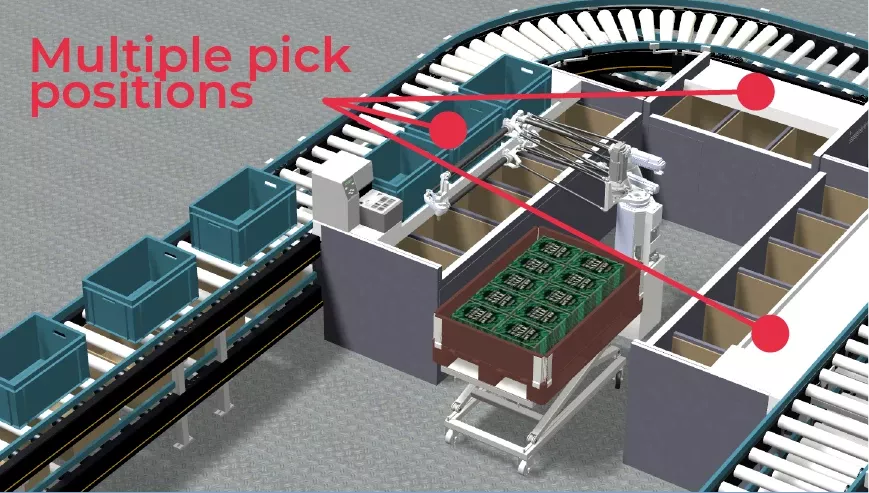

Every additional pick position mean that more frequently picked articles can be kept close to the pick station making them instantly available for coming orders without having to travel back to the backend storage. This buffer reduces the number of duplicate bins you need to keep in a system to avoid starvation and help increase the efficiency of your automated storage systems.

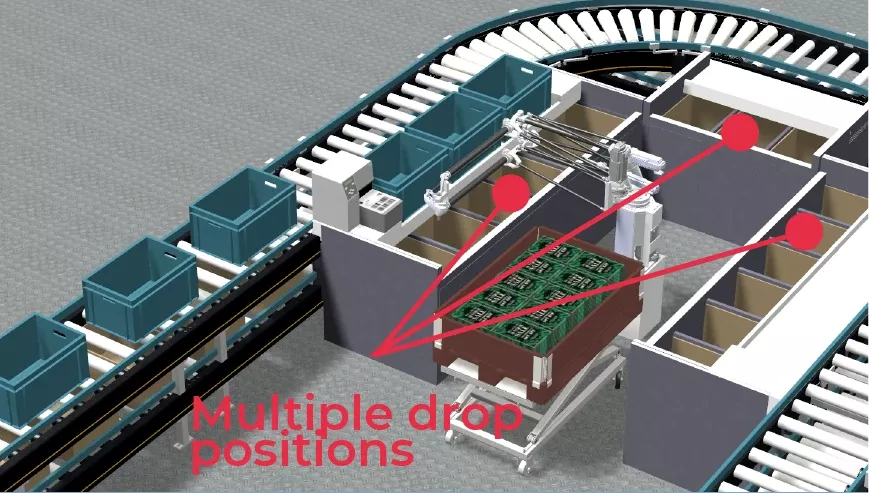

By adding more drop positions at each pick station you can handle more customer orders in parallel thus avoiding dead waiting time for specific articles being retrieved from the storage. It also allows a cost effective way to increase productivity without significantly having to increase the capacity of the automated storage system.